The stable operation of a Box Phone Farm largely depends on a critical aspect that is often underestimated: thermal management. A poor Box Phone Farm cooling system not only causes performance drops in automation processes but also significantly shortens hardware lifespan. At GenFarmer, as specialists in MMO and large-scale digital marketing solutions, we know that heat is one of the biggest enemies of profitability. Therefore, in this article, we explain why traditional cooling methods are insufficient and how our hardware design is optimized to keep your operations running continuously, safely, and at a controlled temperature.

1. The Thermal Challenge in Modern Box Phone Farms

Operating an infrastructure of 20, 40, or up to 100 devices in a confined space generates heat density comparable to that of a high-end server. Without a professional Box phone farm cooling strategy, processors trigger thermal throttling, reducing their frequency to cool down, which causes unexpected app closures and loss of synchronization in your campaigns.

1.1. Why are homemade methods not enough?

Many entrepreneurs try to cool their farms with domestic fans or ambient air conditioning. However, this does not attack the root of the problem. Heat generated on the motherboard must be efficiently evacuated from inside the chassis. The lack of directed airflow creates hotspots where stagnant air reaches dangerous temperatures for sensitive electronic components.

2. Box Phone Farm Cooling: Critical Performance Factors

To understand the importance of advanced cooling, it is necessary to analyze how temperature affects different levels of a phone farm:

- Operating System Stability: Excessive heat corrupts Android kernel processes, causing constant reboots.

- Storage Lifespan: Flash memories suffer accelerated physical degradation at high temperatures, resulting in the loss of critical account data.

- Network Efficiency: Wi-Fi modules and Ethernet controllers lose performance with heat, increasing latency in automated marketing tasks.

An effective Box phone farm cooling system must integrate airflow design, fan static pressure, and active dissipation of custom motherboards.

3. GenFarmer’s Solution: Superior Dissipation Engineering

At GenFarmer, we have redefined hardware for mass automation. Our cases are not simple containers; they are optimized thermal systems. By developing our Box Phone Farm, we removed unnecessary components that obstruct air, such as screens and batteries, leaving the motherboard exposed for direct and efficient cooling.

3.1. High Static Pressure Fans

Our equipment incorporates industrial fans that move a massive volume of air through the tight spaces between boards. This ensures that cool air enters through front ports and hot air is expelled quickly, avoiding residual heat buildup.

3.2. Chassis with Directed Airflow

The design of our metal structure allows each node to receive constant airflow. Unlike open structures, our closed design channels wind exactly over the chipsets that generate 90% of the heat, guaranteeing total operational stability.

4. Comparison: Passive Cooling vs. GenFarmer Solution

| Feature | Homemade Systems | GenFarmer Solution |

|---|---|---|

| Cooling Type | Passive or inefficient ambient | Active industrial high pressure |

| Temperature Control | Non-existent or manual | Real-time digital monitoring |

| Process Stability | Low due to thermal throttling | Maximum, no performance drops |

| Durability | Short component lifespan | Hardware designed for 24/7 operation |

5. Best Practices for Thermal Maintenance

Even with the most advanced Box phone farm hardware, it is vital to follow operational guidelines to maximize Box phone farm cooling:

5.1. Strategic Positioning

Never stack boxes without leaving a minimum safety space to avoid obstructing fans. Rear and side air outlets must be clear to allow heat evacuation without return.

5.2. Software Monitoring

Use the GenFarmer management panel to supervise CPU temperature and storage status of each node. If you detect a heat increase, you can restart specific nodes or adjust work cycles to prevent damage.

5.3. Hardware Maintenance

Dust is a critical thermal insulator. We recommend periodically cleaning fans and the chassis interior with dry air to ensure cooling capacity stays like the first day.

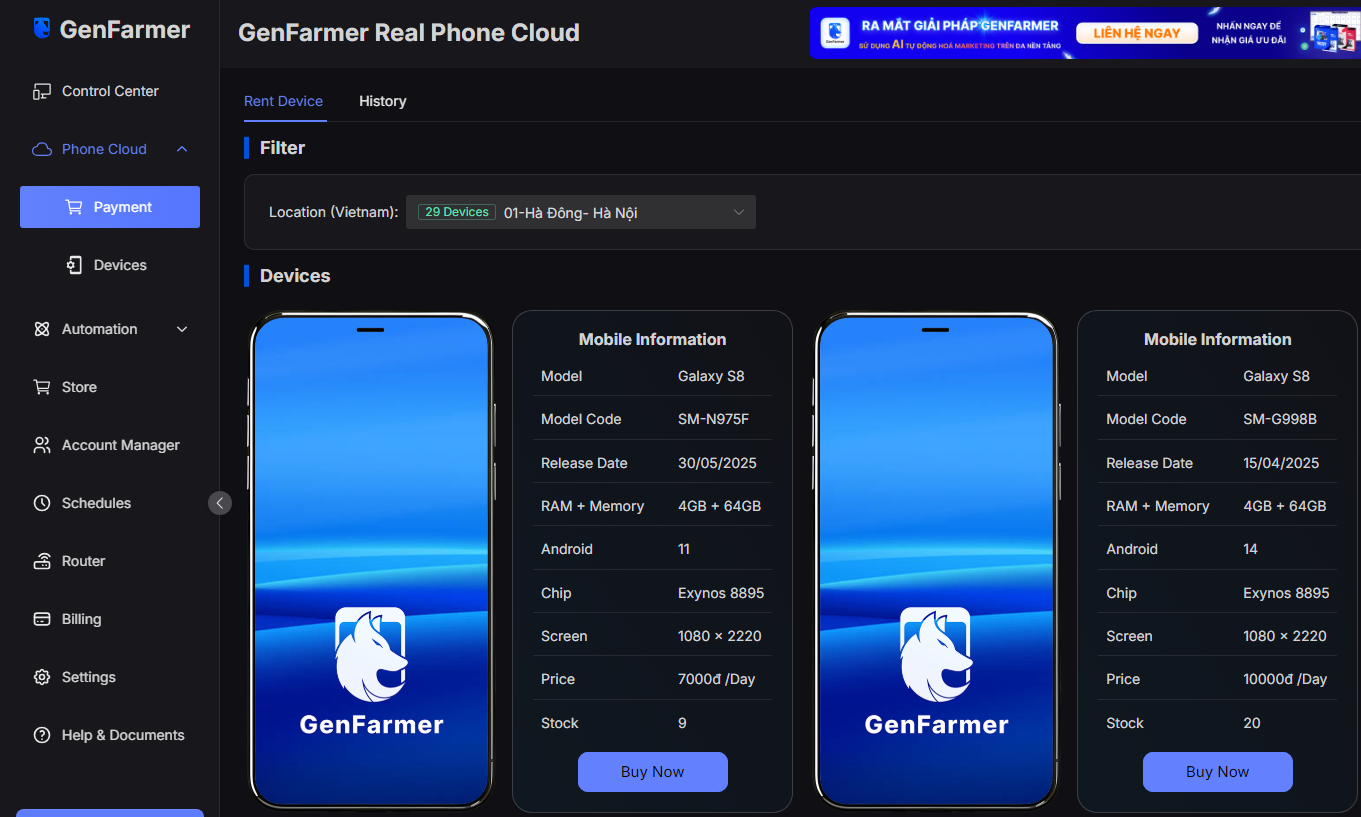

6. Cloud Phone: The Fully Managed Cooling Alternative

If you prefer not to manage physical hardware or are in an environment without climate control, our Cloud Phone solution is the answer. In this model, GenFarmer assumes total responsibility for infrastructure and cooling in professional data centers. You get a powerful, cool, and stable Android instance, accessible from anywhere without worrying about physical maintenance.

The transition to professional automation requires leaving behind improvised solutions. GenFarmer hardware is the stable base digital marketing experts need to scale their projects safely.

Conclusion

Box phone farm cooling is not a luxury, it is the pillar that supports your MMO business. A system that overheats is a system that generates losses. By choosing GenFarmer, you invest in engineering designed by experts who understand that thermal stability is the difference between success and operational failure.

Are you ready to eliminate heat problems in your infrastructure? Do not let temperature stop your growth. Visit our Box Phone Farm store to purchase equipment with industrial cooling or discover our Cloud Phone options for a 100% managed experience. Optimize your performance today with GenFarmer!